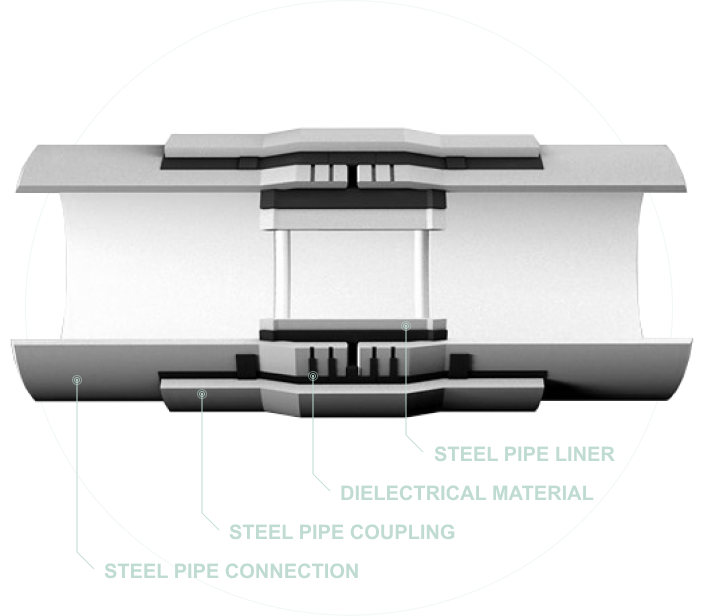

Stray and electric currents cause corrosion and leakeges. The main problem is that the section of the pipeline exposed to electrochemical corrosion is impossible or extremely difficult to calculate in advance. Cathodic protection is the only way to protect metal from rapid corrosion damage. Currently, corrosion causes significant economic damage to enterprises. That is why in 2000 our company developed and patented special technology monolithic insulating joint (NEMS).

The NEMS is designed for electrical separation and balancing the potential difference between pipelines. Outperforms many existing joints in terms of reliability and strength. In trouble-free operation there are more than 400 thousand NEMS on gas pipelines, oil pipelines, product pipelines, high-pressure water pipelines with a working pressure of up to 245 bar, in housing and communal services, etc.

Based on 30 years of experience in the oil and gas industry, we recommend using monolithic isolating joint (NEMS).